Comprehensive Guide to ZF 6HP Generation 2 solenoid diagram PDF Transmission

When venturing into the realm of automotive transmissions, it’s highly likely that you’ll encounter the ZF 6HP Generation 2, a popular choice due to its exceptional performance and durability. At the heart of this transmission are the solenoids—vital components that regulate fluid flow to ensure seamless gear shifts and proper overall function. However, when transmission issues arise, solenoids are often the root cause, affecting the smooth operation of the vehicle. For those looking to resolve these problems, resources like the “ZF 6HP Generation 2 solenoid diagram PDF” provide detailed insight into the configuration of these solenoids, allowing for easier diagnostics and repairs. These diagrams are indispensable tools, especially when troubleshooting shifting issues or trying to maintain peak performance.

Understanding how solenoids work within the ZF 6HP Generation 2 transmission system is crucial for anyone from professional mechanics to DIY car enthusiasts. A faulty solenoid can lead to anything from delayed shifting to more severe transmission failures, but having access to a ZF 6HP Generation 2 solenoid diagram PDF can significantly simplify the repair process. Equipped with this information, individuals can tackle transmission repairs with confidence, identifying problematic solenoids and restoring their vehicle’s functionality. In essence, mastering the intricacies of solenoids and their diagrams enables anyone to keep their vehicle running smoothly, ensuring the transmission operates with precision.

The Essential Role of Solenoids in the ZF 6HP Generation 2 Transmission

Solenoids are indispensable components in the ZF 6HP Generation 2 automatic transmission, influencing how the vehicle performs. These electromechanical devices are tasked with controlling the flow of transmission fluid, a key factor in determining how well the gears shift and how smoothly the transmission operates. By modulating the fluid flow, solenoids ensure that gear changes occur at the right time and in the right manner, which is crucial for maintaining optimal vehicle performance.

When an electric current passes through the solenoid coil, it creates a magnetic field. This magnetic field is responsible for engaging or disengaging specific mechanical elements within the transmission system. The precise control over these components allows for a smoother and more efficient transfer of power from the engine to the wheels. This functionality is essential for the vehicle’s overall drivability, as it ensures that gear transitions are executed with precision, minimising disruptions in power delivery.

In summary, solenoids function much like valves within the transmission system, managing hydraulic pressure to facilitate seamless gear shifts. Their operation is crucial for avoiding jerky or unpredictable gear changes, which can negatively impact driving comfort and vehicle reliability. Therefore, understanding how solenoids work and ensuring their proper maintenance is important for anyone who relies on a ZF 6HP Generation 2 transmission, as issues with these components can lead to significant performance problems or even complete transmission failure.

Key Solenoids in the ZF 6HP Generation 2 Transmission

Pressure Control Solenoid: Precision in Hydraulic Regulation

The pressure control solenoid is essential for managing hydraulic pressure within the ZF 6HP Generation 2 transmission. It adjusts pressure levels based on engine load and speed, ensuring smooth and efficient gear changes. This solenoid plays a critical role in maintaining optimal performance and enhancing driving comfort by reacting to real-time changes in the vehicle’s operation.

Shift Solenoid: Enabling Seamless Gear Transitions

The shift solenoid is pivotal in controlling gear changes by managing the engagement of clutches and brakes. This solenoid enables precise gear shifts, contributing to a smoother driving experience. Its ability to handle the intricate process of engaging and disengaging transmission components ensures that transitions between gears are fluid and seamless.

Torque Converter Lock-Up Solenoid: Enhancing Efficiency on the Highway

The torque converter lock-up solenoid improves driving efficiency, particularly during highway cruising. By locking the torque converter at specific speeds, it enhances fuel economy and reduces engine strain. This solenoid plays a crucial role in optimising the vehicle’s performance and overall efficiency during long-distance driving.

Mastering the Solenoid Diagram for the ZF 6HP Generation 2 Transmission

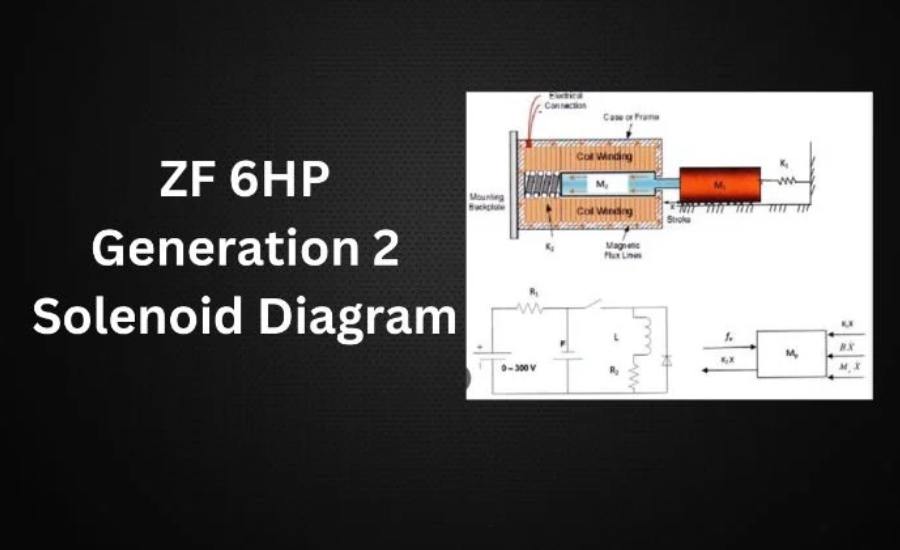

Getting Started with the Solenoid Diagram

Interpreting a solenoid diagram for the ZF 6HP Generation 2 transmission can initially seem challenging. However, once you become acquainted with the symbols and the layout, it becomes much easier to understand. Begin by identifying the key components within the diagram. Look for labels that specify each solenoid’s role, such as “shift,” “pressure,” or “lockup” solenoids. Recognizing these labels will help you grasp the function of each solenoid in the transmission system.

Understanding Wiring Connections

Next, focus on the wiring connections depicted in the diagram. The lines on the diagram illustrate the electrical pathways, which are essential for understanding how power is distributed through the various solenoids. Being able to trace these connections is vital for diagnosing and troubleshooting issues related to solenoid malfunctions. Accurate knowledge of these electrical pathways allows for more effective maintenance and repair work.

Utilising Colour Coding and Additional Information

Be sure to examine any colour coding included in the diagram, as it often indicates different functions or operational states of the solenoids. Additionally, refer to any legends or notes provided within the ZF 6HP Generation 2 solenoid diagram PDF. These supplementary details are crucial for enhancing your troubleshooting capabilities and increasing your proficiency with the transmission system. Understanding these aspects will boost your confidence in managing and repairing the transmission effectively.

Identifying Common Issues Zf 6hp Generation 2 Solenoid Diagram Pdf Transmission

Recognizing Delayed Shifting

When troubleshooting solenoid problems in the ZF 6HP Generation 2 transmission, the first sign to watch for is delayed shifting. If the transmission hesitates or takes longer than usual to change gears, it often indicates an issue with one or more solenoids. This delay suggests that the solenoids may not be regulating hydraulic pressure effectively, impacting the timing of gear changes.

Observing Erratic Gear Shifts and Dashboard Alerts

Another symptom of solenoid malfunction is erratic or harsh gear shifts. If the vehicle seems to slam into gears or experiences jarring transitions, this could be due to a solenoid failing to maintain the correct hydraulic pressure. Additionally, pay attention to any warning lights that appear on the dashboard. These alerts can directly point to solenoid issues and should be addressed promptly to avoid further complications.

Monitoring Unusual Noises and Diagnostic Codes

Unusual noises, such as whining or grinding sounds, during operation can also signal problems with the solenoids. These sounds often indicate that the solenoids or their connections are not functioning properly. To further diagnose solenoid issues, use an OBD-II scanner to check for error codes related to the transmission system. Regular diagnostic checks can help identify potential problems early, allowing for timely repairs and preventing more serious issues.

Effective Maintenance of Zf 6hp Generation 2 Solenoid Diagram Pdf Transmission

Conducting Regular Inspections

To ensure the solenoids in the ZF 6HP Generation 2 transmission remain in optimal condition, regular inspections are essential. Look for common issues such as signs of wear, corrosion, or leaks around the solenoid connections. Identifying these problems early can prevent them from worsening and affecting the overall performance of the transmission.

Using OEM Parts and Proper Installation Techniques

When it becomes necessary to replace a solenoid, always opt for OEM (Original Equipment Manufacturer) parts. These components are specifically designed for compatibility with your transmission system, ensuring reliable performance. Before installing a new solenoid, make sure to clean the installation area thoroughly. This step helps prevent debris from causing operational issues or further damage. Additionally, adhere to the correct torque specifications during reassembly. Incorrect torque can either damage the solenoid or lead to fluid leaks, compromising the functionality of your transmission.

Monitoring Performance and Seeking Professional Help

Once the solenoid replacement is complete, it’s crucial to closely monitor the transmission’s performance. Pay attention to any unusual behaviour, as it may indicate that additional issues need to be addressed. If you are uncertain about performing maintenance or repairs yourself, consider seeking professional assistance. Expert servicing can be a worthwhile investment, especially when dealing with the complex components of the ZF 6HP Generation 2 transmission, ensuring proper care and avoiding potential complications.

FAQs

Q1. What are solenoids, and why are they crucial for the ZF 6HP Generation 2 transmission?

A. Solenoids are electromechanical devices that control the flow of transmission fluid, affecting gear shifts and overall transmission performance. In the ZF 6HP Generation 2 transmission, they ensure smooth and efficient operation by regulating hydraulic pressure and managing gear transitions.

Q2. How can I identify problems with solenoids in my ZF 6HP Generation 2 transmission?

A. Common signs of solenoid issues include delayed shifting, erratic or harsh gear changes, warning lights on the dashboard, and unusual noises like whining or grinding. Using an OBD-II scanner can also help diagnose solenoid-related problems by providing error codes.

Q3. What should I look for when inspecting solenoids?

A. During inspections, check for wear, corrosion, or leaks around solenoid connections. Routine inspections can detect issues early, helping to avoid more severe problems with transmission performance.

Q4. Why is it important to use OEM parts for solenoid replacement?

A. OEM (Original Equipment Manufacturer) parts ensure compatibility and reliable performance with your transmission system. Using non-OEM parts may result in improper fit or function, potentially causing further issues.

Q5. How should I proceed if I encounter difficulties with solenoid maintenance or repairs?

A. If you’re unsure about performing solenoid maintenance or repairs yourself, it’s advisable to seek professional assistance. Expert servicing can help ensure proper handling of complex transmission components and prevent potential complications.

Conclusion

Proper maintenance and comprehension of the solenoids in the ZF 6HP Generation 2 transmission are essential for achieving smooth and dependable vehicle operation. By recognizing common issues, using OEM parts for replacements, and conducting regular inspections, you can effectively manage and troubleshoot solenoid-related problems. For complex repairs, don’t hesitate to seek professional assistance to keep your transmission operating at its best.

Stay In Touch For More Updates And Alerts: England Tribune